Voomig excels in bringing quality to the hot tub and outdoor spa enterprise through through our careful development of effective techniques. With a full production line, our production team is keen on creating, designing, and providing Chinese-made spas that can surpass international competition at much lower prices.

With our control over the supply chain network, we search for the right parts that meet international standards. From stainless steel to acrylic boards, we inspect all of the materials we receive by checking for flaws and defects. We only get parts from trusted suppliers locally and abroad.

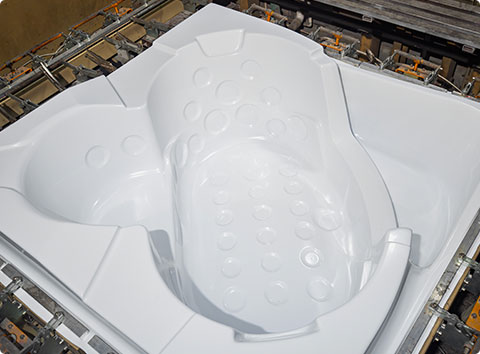

Forming involves placing a softened acrylic board on a special heat platform to set it at a certain temperature. With our technical expertise, we get the exact shape with the help of the vacuum former. Our process is precise in how we help shape every tub to meet your requirements.

Our factory’s exclusive coating technology ensures that our tubs are durable enough to hold maximum capacity water and people. We make sure that our tub models are not at risk of leaking or easily breaking. Reinforcing the exterior of our tubs with resin fiber helps ensure that the surface maintains regular temperature.

As an exclusive technique developed by our factory, foaming allows our tubs to be processed with quality epoxy resin after a spa body is formed. Our non-stick insulation foaming gives our spas a longer lifespan as it provides excellent insulation and infiltration prevention for all of our tubs.

At the assembly area, our workers put together all the nozzles, pipes, pumps, heaters, control systems, lighting and other necessary pieces. We also install cabinets and the bottom base, which is a 5-millimeter thick fiberglass sprayed FRP that is hard and durable, allowing it to be placed in different surfaces.

Valves are installed at the inlet and outlet of each pump, which are easily removed by just unscrewing the valve. We use a stainless steel pipe clamp on each pipe to keep the water pipe in place and reduce water leakage to add much value for your customers.

A screw will install the shirt rim, which is a single piece equipped with a thick foil insulation cotton which is held in place with stainless steel bars. Owners can easily open the shirt rim, which will give easy access to the inside of the tub. Our skirting gives our tubs a beautiful and well-insulated exterior.

We conduct one more test to determine the existence of any defects on our tubs, mainly by pouring large amounts of water and testing their durability. Within two hours, we can guarantee that our tubs are in working condition. Before packaging, our workers will polish the tubs and prepare them for delivery.